We are happy to announce that a new paper on “Computational co-design framework for coreless wound fibre-polymer composite structures” has been published in the Journal of Computational Design and Engineering, which is the collaborative work of researchers from the fields of architecture, structural engineering, engineering geodesy, textile and systems engineering, and aerospace engineering.

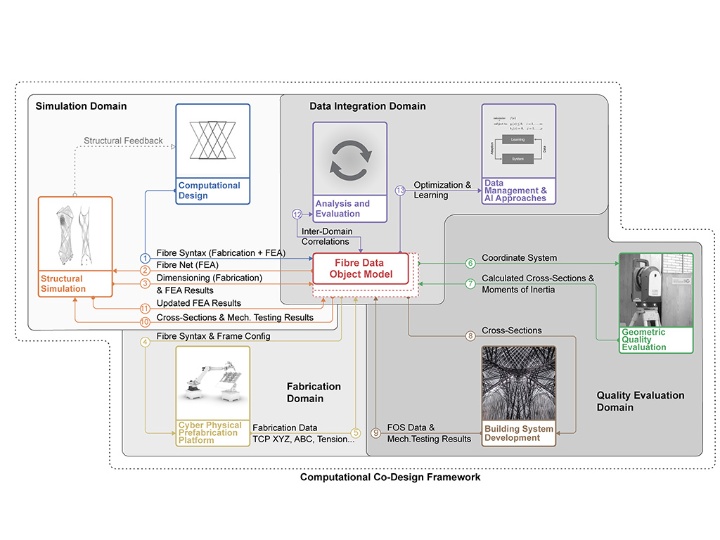

The paper introduces the use of a shared object model acting as a central data repository that facilitates interdisciplinary data exchange and the investigation of correlations between domains. The application of the developed computational co-design framework is demonstrated in a case study in which the data are successfully mapped, linked and analysed across the different fields of expertise. The results showcase the framework’s potential to gain a deeper understanding of large-scale coreless wound filament structures and their fabrication and geometrical implications for design optimisation.

Abstract

In coreless filament winding, resin-impregnated fibre filaments are wound around anchor points without an additional mould. The final geometry of the produced part results from the interaction of fibres in space and is initially undetermined. Therefore, the success of large-scale coreless wound fibre composite structures for architectural applications relies on the reciprocal collaboration of simulation, fabrication, quality evaluation, and data integration domains. The correlation of data from those domains enables the optimization of the design towards ideal performance and material efficiency. This paper elaborates on a computational co-design framework to enable new modes of collaboration for coreless wound fibre–polymer composite structures. It introduces the use of a shared object model acting as a central data repository that facilitates interdisciplinary data exchange and the investigation of correlations between domains. The application of the developed computational co-design framework is demonstrated in a case study in which the data are successfully mapped, linked, and analysed across the different fields of expertise. The results showcase the framework’s potential to gain a deeper understanding of large-scale coreless wound filament structures and their fabrication and geometrical implications for design optimization.

Congratulations to everyone involved!

Please find the full open access paper here.