A new shared paper on “Integrative structural design of a timber-fibre hybrid building system fabricated through coreless filament winding: Maison Fibre” has been published in the Journal of Building Engineering.

Abstract

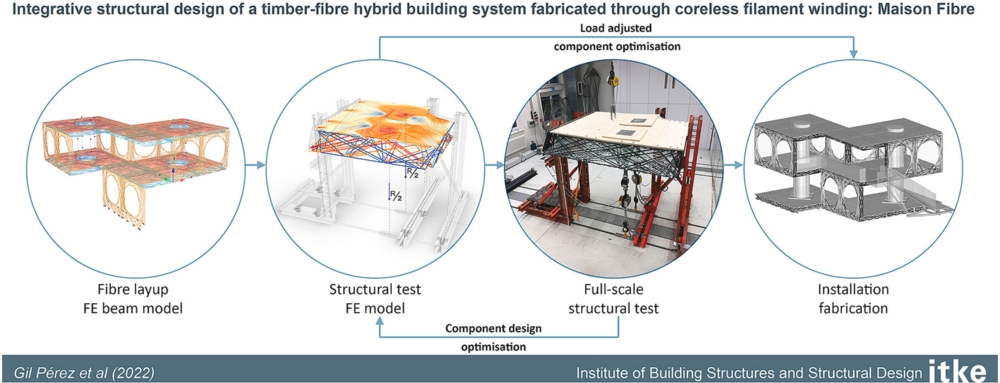

Coreless filament winding is a robotic fabrication technique in which conventional filament winding is modified to reduce the core material to its minimum. This method was showcased and developed through a series of pavilions demonstrating its potential to create lightweight structures. The latest project, Maison Fibre, goes one step further and adapts the fabrication into a hybrid structure combining fibre-polymer composites (FPC) with laminated veneer lumber (LVL) to allow for walkability. The result is the first multi-storey building system fabricated with this novel technique. During the integrative design process of the slab system, the optimum fibre layup was negotiated between the timber support span, load induction, boundary conditions, and material amount required. A total of four iterations of the hybrid component were load tested and compared with the maximum enveloped forces resulting from the global structural simulation. The full-scale load tests were used to calibrate the refined structural simulation of the slab components. The experimental process allowed for material reduction and validated the structural system's capability to withstand the design forces. In addition, the fibre layup was tailored and load adapted for the non-tested wall and slab components of the installation using the test results and achieving further material optimization. This publication describes the integrative design process of the hybrid slab system from initial concepts to the iterative optimization of the structural system, demonstrating its potential for future applications.

Congratulations to Marta Gil Pérez (ITKE), Nikolas Früh (ITKE), Riccardo La Magna (ITKE) and Prof. Dr. Jan Knippers (ITKE)!

Please find the full open access paper here.