Nikolas Früh and Prof. Jan Knippers published an article on Multi-Stage Filament Winding in Composite Structures.

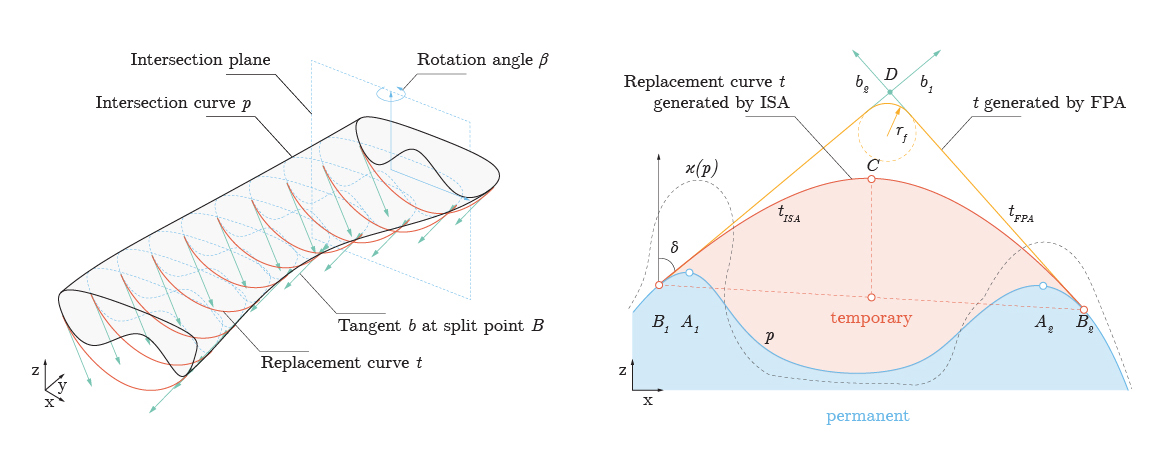

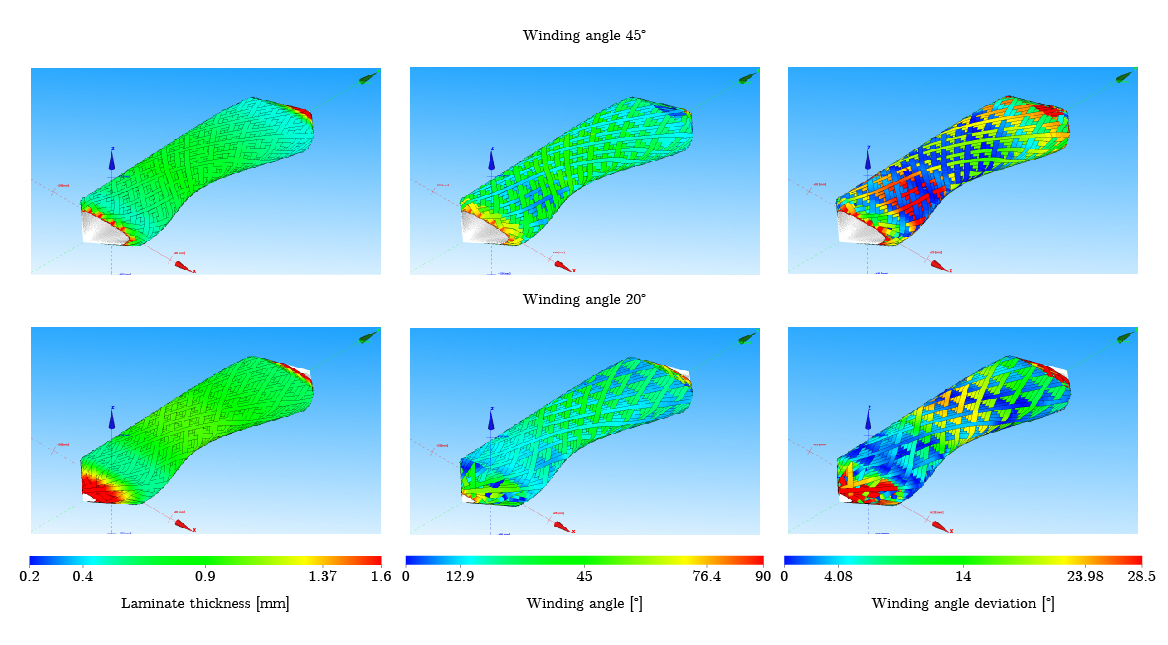

The Multi‐Stage Filament Winding (MSFW) method is being developed to expand the geometrical possibilities of filament winding. The fabrication method enables the sustainable production of lightweight fibre composites with complex geometries. MSFW allows for great control of material parameters and laminate geometry. The article explains the method and focuses on the geometry analysis and generation that is required to analyse components and generate the necessary temporary geometries for fabrication using MSFW.

Abstract

The multi-stage filament winding (MSFW) method enables the sustainable production of lightweight fibre composites with complex geometries. Double curved components, even with undercuts, are analysed and concave areas which are not suitable for filament winding are replaced by convex temporary geometries. Permanent and temporary mandrel parts are combined for the stage-based fabrication method. The sand composites developed for MSFW mandrels can be washed out using water. The sand can be reused. This paper introduces the fabrication method, presents the status of the research, and focuses on the geometry generation algorithm of the integrative design process.

The full article can be accessed here.