On 10 November 2022, Pascal Mindermann presented the outcome of his doctoral research titled Advancements in coreless filament winding towards a digital process characterization with distinction in front of the doctoral committee. The doctoral committee consisted of Prof. Dr. rer. nat. habil. Marc Kreutzbruck (IKT) as chairman, Prof. Dr.-Ing. Götz T. Gresser (ITFT) as supervisor and first examiner, and Prof. Dipl. AA (Hons) Achim Menges (ICD) as second examiner.

Many congratulations to Pascal Mindermann on this outstanding achievement!

Pascal Mindermann presenting his doctoral research

Pascal Mindermann presenting his doctoral research

Abstract Doctoral Research

Coreless filament winding is an emerging additive manufacturing process for generating fiber-reinforced thermoset composite structures. An impregnated fiber bundle is spanned freely between spatially arranged point-like anchors, defining the lattice geometry of the fabricated components. This design freedom, combined with the automation of the process, marks coreless filament winding as a valuable contribution to the spectrum of lightweight manufacturing technologies. However, coreless filament winding still requires several advancements to deliver its potential to mechanical engineering and architectural applications. Mechanical engineering demands efficiency to meet climate neutrality and high-performance structures driven by technical innovation. In conjunction to the challenges, architecture faces an increasing need for building floor space caused by population growth, while productivity stagnates due to missing digitalization.

The adoption of coreless filament winding is held back by inherent variations in the parameters describing the process and the fabricated structures. Process parameter fluctuations combine with material deviations. Safety factors and resource consumption increase as these variations translate into uncertainties in the design process.

Therefore, this thesis aims to improve the characterization of the coreless filament winding process.

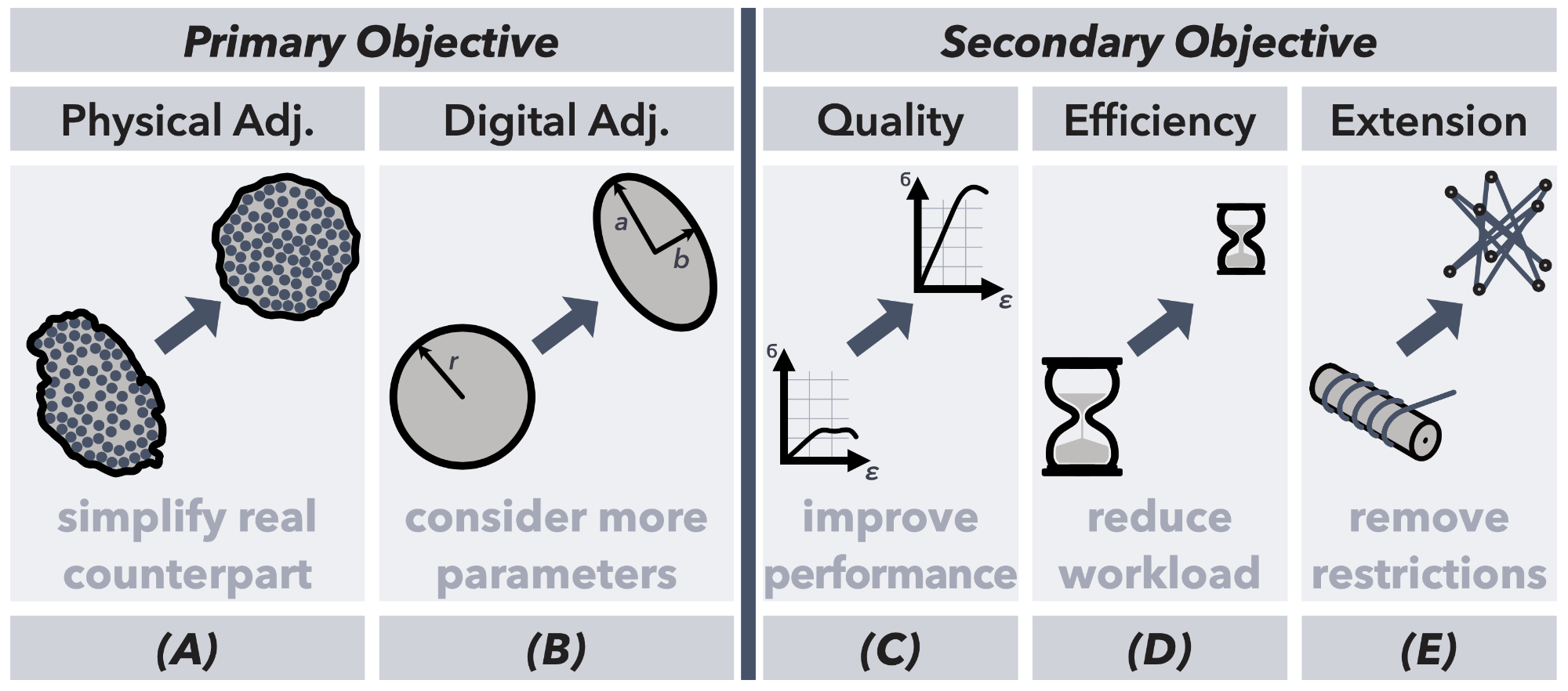

Objectives of the doctoral research

Objectives of the doctoral research

An enhanced digital representation realized this characterization, as the primary objective was to improve the consistency between the digital model and the physical counterpart. The primary objective was achieved by implementing adjustments in the physical as well as in the digital domain. In parallel, this thesis also realized advancements in the quality of the fabricated structures and the efficiency of the process. Furthermore, the process capabilities were extended to new features and applications. Coreless filament winding was considered holistically based on four research approaches as follows: fabrication system, the material system, the load induction, and the computational infrastructure.

The cumulative advancement extracted from the comprised academic contributions, distributed across the research approaches, confirms the overarching improvement of the considered process evaluation criteria through a consistent digital characterization. Moreover, the improved understanding of the peculiarities of coreless filament winding allows for more effective management of specific requirements in the future by simplifying the decision-making during the design process, covering all process aspects.

Pascal Mindermann's doctoral resarch consisted of eleven papers on the topics of:

Fabrication

- Robotic 3D deposition of impregnated carbon rovings with gradient properties for primary structures

- Additive Manufacturing of Large Coreless Filament Wound Composite Elements for Building Construction

- Development of an Impregnation End-Effector with Fiber Tension Monitoring for Robotic Coreless Filament Winding

Material

- Material Monitoring of a Composite Dome Pavilion Made by Robotic Coreless Filament Winding

- Investigation of the Fabrication Suitability, Structural Performance, and Sustainability of Natural Fibers in Coreless Filament Winding

- Pultrusion-winding: A novel fabrication method for coreless wound fiber-reinforced thermoset composites with distinct cross-section

Load Induction

- Investigation of different load transmission concepts for coreless filament wound structures

- Adaptive winding pin and hooking capacity model for coreless filament winding

- Implementation of fiber-optical sensors into coreless filament-wound composite structures

Computation

- Design of Fiber-Composite/Metal-Hybrid Structures Made by Multi-Stage Coreless Filament Winding

- Computational co-design framework for coreless wound fibre-polymer composite structures