The University of Stuttgart's excellence clusters, SimTech and IntCDC, have achieved a significant milestone in advancing construction science. Their collaborative research, "Bayesian Inference for Modelling Uncertainty in Non-Standard Building Systems," will be presented at the Design Modeling Symposium (DMS2024) in Kassel, Germany, epitomizes the power of interdisciplinary cooperation.

The paper, co-authored by Fabian Kannenberg (ICD) from IntCDC and Tim Schneider (KI) from SimTech, alongside other esteemed researchers, addresses a critical challenge in modern construction: managing and quantifying uncertainty in non-standard building systems, with a particular focus on coreless filament winding.

This collaboration between SimTech and IntCDC exemplifies how the strengths of these two clusters can complement each other. SimTech is renowned for its expertise in data-integrated simulation science, particularly in developing advanced computational models and simulations. Their proficiency in Bayesian inference and probabilistic modeling provides robust frameworks for handling complex data sets and predicting outcomes with greater accuracy. This expertise is crucial for understanding and managing the inherent uncertainties in construction processes.

On the other hand, IntCDC is at the forefront of integrative computational design and construction, pushing the boundaries of architectural innovation. IntCDC's strength lies in its ability to integrate various aspects of design, material science, and robotics to develop sustainable and efficient building systems. Their pioneering work in coreless filament winding showcases how innovative fabrication techniques can revolutionize construction.

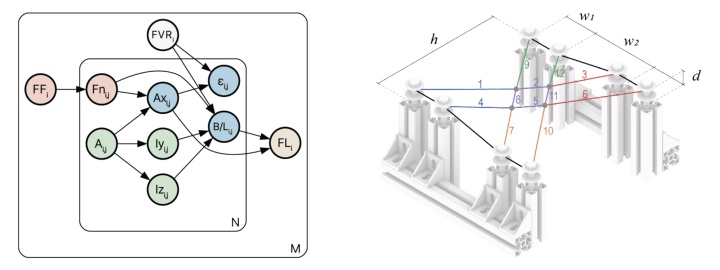

By integrating Bayesian inference techniques from SimTech with IntCDC's cutting-edge fabrication methods, this research offers a comprehensive solution for modeling and managing uncertainty in novel construction processes. The proposed framework combines data from fabrication parameters, geometry, material properties, and structural response metrics, creating a holistic approach to design and decision-making in architecture.

This collaborative project highlights several key contributions. The Bayesian inference framework introduced in this research is tailored specifically for modeling uncertainty in coreless filament winding. This probabilistic method allows for the integration and analysis of heterogeneous data sources, providing a robust tool for architects and engineers to make informed decisions. Additionally, by leveraging data from multiple domains, including fabrication, geometry, and material properties, the research facilitates an optimized design process that enhances the performance and material efficiency of building systems. The innovative fabrication techniques employed, such as coreless filament winding, eliminate the need for complex and wasteful molds, enabling the production of highly material-efficient building elements.

The success of this collaboration opens new avenues for further research and innovation. Future work will explore the integration of additional data from robotic manufacturing processes and sensor measurements, aiming to further refine and optimize fabrication parameters. This ongoing collaboration will continue to push the boundaries of what's possible in construction science, setting new standards for efficiency, sustainability, and innovation.

This partnership between SimTech and IntCDC is a testament to the transformative potential of interdisciplinary collaboration. By combining their unique strengths, these excellence clusters are paving the way for groundbreaking advancements in the construction industry. Their joint research not only addresses current challenges but also lays the foundation for a future where data-integrated design and innovative fabrication techniques are the norm, driving the industry towards greater sustainability and performance.

This research was supported by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation) under Germany’s Excellence Strategy – EXC 2120/1 – 390831618 and EXC 2075 – 390740016. The authors also acknowledge the support of the Stuttgart Center for Simulation Science (SimTech) and the Ministry of Science, Research and Arts Baden-Württemberg via the Artificial Intelligence Software Academy (AISA).

Kannenberg, F., Gil Pérez, M., Schneider, T., Staab, S., Knippers, J., Menges, A.: 2024, Bayesian Inference for Modelling Uncertainty in Non-Standard Building Systems. Scalable Disruptors. DMS 2024 (Proceedings of the Design Modelling Symposium 2024), pp. 69-80. (doi: 10.1007/978-3-031-68275-9_6)